October 16, 2019 at 3:19 am | Updated October 16, 2019 at 3:19 am | 6 min read

Potato Dry Matter Testing

Potato (Solanum tuberosum) is the third most important crop grown globally, and the annual production exceeds 300 million metric tons. Usually, dry matter is used in agriculture to identify the harvest time of fruits and vegetables. Since potatoes are underground tubers, this application of dry matter is not useful for this vegetable. Despite this, dry matter estimation is very important in potato production to ensure quality control in the supply chain and processing for human and animal consumption.

The Modest Potato & Its Many Uses

Potatoes form the staple food for millions of people from many countries. Potatoes have a water content that varies from 75 to 85% and the rest is dry matter that contains the nutrients for which potatoes are grown.

Dry matter (DM) in any fruit and plant is the total solid contents minus water content. This consists of structural compounds, carbohydrates, proteins, amino acids, nutrients, pigments, fats, and sugars.

Subscribe to the Felix instruments Weekly article series.

By submitting this form, you are consenting to receive marketing emails from: . You can revoke your consent to receive emails at any time by using the SafeUnsubscribe® link, found at the bottom of every email. Emails are serviced by Constant Contact

For Consumption by People

Potato tubers are consumed, cooked, or fried. Also, they are processed to produce chips, french fries, flakes, granules, and starch. The quality of potatoes in the entire production and supply chain is important, as it can affect the processing of the products.

Dry matter content, total soluble sugars (TSS), and starch concentrations of potatoes are important parameters to establish quality for consumers and industrial use. These parameters affect the texture, yield, and fat content of the different processed products. According to Potato Pro, the preferred dry matter for industrial production of potato products are as follows:

- French Fries 360 – 19.7% DM

- French Fries 400 – 21.7% DM

- French Fries 450 – 24.1% DM

- Potato Chips 400 – 21.7% DM

- Potato Chips 420 – 22.7% DM

- Potato Chips 470 – 25.1% DM

- Dehydrated Products 380 – 20.7% DM

- Dehydrated Products 400 – 21.7% DM

- Dehydrated Products 450 – 24.1% DM

Processors prefer potatoes with higher DM as it is significantly correlated with specific gravity, and potatoes with higher specific gravity are suitable for baking, chipping, frying, and mashing. The amount of DM can also influence the final color of chips, which has to be optimal for consumer satisfaction.

Since potatoes are cultivated worldwide, there are more than 4,000 varieties in use, and they come in different shapes, sizes, and colors. Grading, therefore, forms an important step to regularize the size of potatoes to make them attractive for retail sales for direct consumption. One of the disadvantages of grading is that perfectly good produce is rejected because they are of different sizes or shapes.

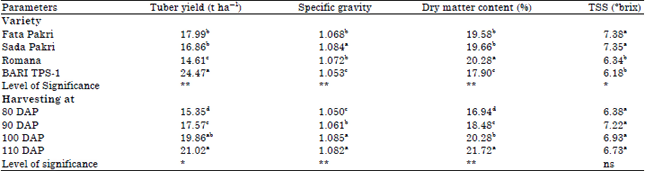

Table 1: Variety, and stage of maturity influence dry matter content, TSS, tuber yield, and specific gravity in potatoes, Soliaman, et al. 2015. (Image credits: https://scialert.net/abstract/?doi=jps.2015.108.115)

Cull Potatoes

The rejected potatoes that are culled are therefore not cast away but used as feed for livestock. Many diseased and damaged tubers also end up as cull potatoes. Grading can be conducted in any stage of the supply chain, producing more cull potatoes.

The nutrients in potatoes are valuable as they are absent in the hay and are, therefore, suitable as feed for livestock. Livestock also prefer them and are known to consume up to 10% of their body weight daily of potatoes.

The amount of dry matter is important even for cull potatoes, as those with higher DM are considered higher in quality and more useful than potatoes with low DM. This is also reflected in the price, as cull potatoes with higher DM are more expensive.

So, the DM of cull potatoes is important for farmers and livestock producers. Potatoes with 25% DM are considered the best, but they should have a DM of at least 15%.

Factors Affecting Dry Matter in Potatoes

It has been found that DM content increases with tuber maturity in potatoes. The crops are harvested when the tubers are fully mature and have the highest DM, specific gravity, and protein content (See Table 1). Though the yield quantity is higher if the crop is harvested earlier, there is a trade-off in terms of quality.

DM content also depends on the variety, location, season, growing methods, and duration of storage. The planting date, adequate but not too much irrigation, and the amount of fertilizers used are the main criteria in growing methods that affect DM content.

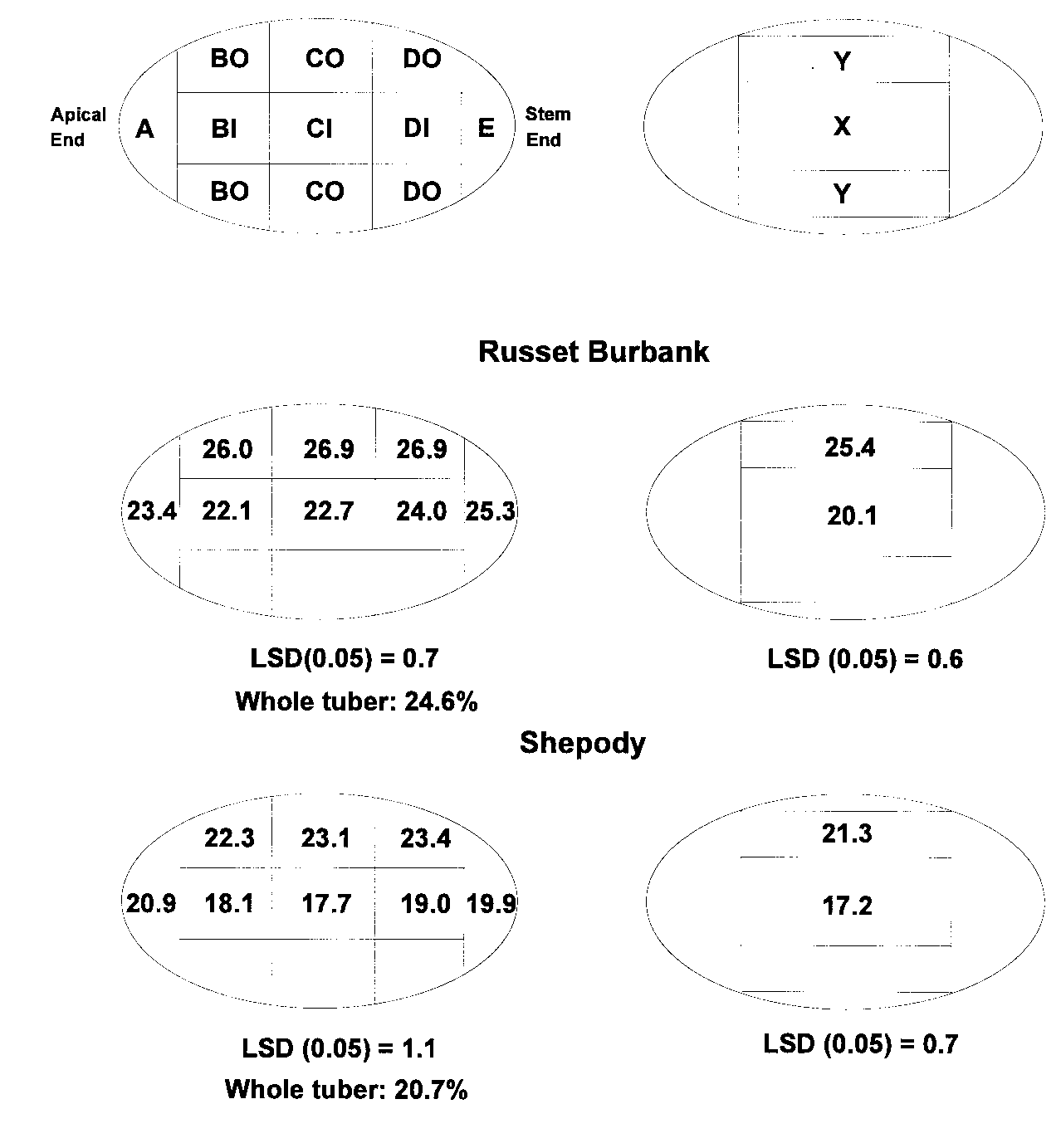

Figure 2: “Diagrammatic of individual sections and mean (n = 100) percent DM in Russet Burbank and Shepody potato tubers (A–E and X, Y refer to areas within tubers while I and O refer to inside and outside, respectively).”Pritchard, M. K. & Scanlon, M. G. 1997 (Image credits: https://www.nrcresearchpress.com/doi/pdf/10.4141/P96-111)

Dry matter and sugars are not evenly distributed within the tuber and can change with the duration of storage (See Figure 1). The centers of the tubers have less DM, especially after many months of storage. There is more DM on the outer portion of the tubers and at the apical and stem tips of the tuber. The distribution of DM within a tuber also depends on the variety. So Shepody tubers showed more variation in the amount of DM and sugars in different parts of the tuber than in the variety Russet Burbank.

Dry Matter Estimation on Farms

Usually, farms use conventional methods to estimate dry matter on the farm. These methods require many tools and space, and they are time consuming.

Potatoes from five different locations are taken and cut into slices. These slices are then mixed, and a sample weighing 50-100 grams is taken. The potato slices are weighed to get the fresh weight before drying.

Many methods of drying are usually used; these include the forced-air oven, microwave, food dehydrator, and Koster Moisture Tester.

- Forced-air oven is usually used to test potatoes on the farm. These are more expensive than domestic ovens. The weighed potatoes are dried for 24 hours at 100° to 105°C.

- Food dehydrators are faster, as it takes only 3-8 hours.

- Micrwave ovens are the fastest drying method, but the drying has to be monitored carefully and done in intervals to prevent the potato sample slices from burning. Each round of drying takes only 30 seconds.

- Koster Moisture Testers are equipment that many livestock farms use to estimate DM of dry hay and other feedstocks. It is an electric appliance that blows warm air to dry the sample. Potatoes can also be dried in it. However, just as in the case of microwaves, the drying has to be monitored closely, and after the first drying phase, if the sample is not dry, the cycle is repeated for another half-an-hour. Therefore, this method of drying is slow.

After the sample no longer loses weight, it can be considered to be completely water-free. The difference in fresh and dry weights is used to calculate the dry matter content.

Modern Tools to Measure Dry Matter

New, small hand-held devices that use Near Infra-Red spectroscopy to detect dry matter are a good alternative to the conventional methods. A device such as the F-750 Produce Quality Meter from Felix Instruments is ideal. Moreover, the F-750 estimates not just DM, but also TSS, as well as internal and external color.

Repeated dry matter estimation is necessary during harvest, several times during storage, culling, and before processing in case of potatoes. Since potatoes are produced in large quantities, this tool makes testing crops easy and cheap. The measurements are quick and non-destructive, so they do not involve a loss of the crop.

Potato Production is Increasing

New tools that help in convenient and quick estimation of DM can help improve producers’ income. They are also useful in grading and sorting potatoes. It is also easier for livestock farmers to optimise their feed mixtures if they know the DM of their cull potatoes. It is estimated that potato production is increasing by 25% in developing countries. So, the relevance of modern tools cannot be over-estimated in this scenario.

—

Vijayalaxmi Kinhal

Science Writer, CID Bio-Science

Ph.D. Ecology and Environmental Science, B.Sc Agriculture

Sources

About No Name. Retrieved from https://www.potatopro.com/about/all?page=2

Agriculture Victoria. (2010, April). Potatoes: Factors affecting dry matter. Retrieved from http://agriculture.vic.gov.au/agriculture/horticulture/vegetables/vegetables-a-z/potatoes/potatoes-factors-affecting-dry-matter

Haase, N. (2003). Estimation of dry matter and starch concentration in potatoes by determination of under-water weight and near infrared spectroscopy. Potato Res.. 46. 117-127. 10.1007/BF02736081.

Pedreschi, F., Mery, D., & Marique. T. (2016). Grading of potatoes. In: Sun DW (ed) Computer vision technology for food quality evaluation, 2nd edn. Academic Press, London, pp 369–382. https://doi.org/10.1016/B978-0-12-802232-0.00015-3

Potato facts and figures. (2019). Retrieved from https://cipotato.org/crops/potato/potato-facts-and-figures/

Pritchard, M.K., & Scanlon, M. G. (1997). Mapping dry matter and sugars in potato tubers for prediction of whole tuber process quality. Retrieved from https://www.nrcresearchpress.com/doi/pdf/10.4141/P96-111

Solaiman, A.H.M., Nishizawa, T., Roy, T.S., Rahman, M., Chakraborty, R., Choudhury, J., Sarkar, D., & Hasanuzzaman, M. (2015). Yield, Dry Matter, Specific Gravity and Color of Three Bangladeshi Local Potato Cultivars as Influenced by Stage of Maturity. Journal of Plant Sciences, 10: 108-115. DOI: 10.3923/jps.2015.108.115

University of Idaho Extension. Norell, R. J., Glaze, Jr., J. B., Chahine, M., & Olsen, N. Measuring Potato Dry Matter Content on the Farm. Retrieved from https://www.extension.uidaho.edu/publishing/pdf/CIS/CIS1219.pdf

Waterer, D., & Thomson, J. Saskatchewan. Potato Cull Pile Management. Retrieved from https://www.saskatchewan.ca/business/agriculture-natural-resources-and-industry/agribusiness-farmers-and-ranchers/crops-and-irrigation/horticultural-crops/pot

Why Dry Matter Matters. (2016, April 20). Retrieved from https://felixinstruments.com/use-case/why-dry-matter-matters/

Related Products

- F-901 AccuRipe & AccuStore

- F-751 Melon Quality Meter

- F-751 Kiwifruit Quality Meter

- F-750 Produce Quality Meter

- F-751 Avocado Quality Meter

- F-751 Mango Quality Meter

- F-900 Portable Ethylene Analyzer

- F-950 Three Gas Analyzer

- F-920 Check It! Gas Analyzer

- F-960 Ripen It! Gas Analyzer

- F-940 Store It! Gas Analyzer

Most Popular Articles

- Spectrophotometry in 2023

- The Importance of Food Quality Testing

- NIR Applications in Agriculture – Everything…

- The 5 Most Important Parameters in Produce Quality Control

- Liquid Spectrophotometry & Food Industry Applications

- Melon Fruit: Quality, Production & Physiology

- Ethylene (C2H4) – Ripening, Crops & Agriculture

- Active Packaging: What it is and why it’s important

- Guide to Fresh Fruit Quality Control

- Understanding Chemometrics for NIR Spectroscopy