October 21, 2020 at 9:15 pm | Updated October 21, 2020 at 9:15 pm | 8 min read

There is inherent variability in the chemical composition of fruits, vegetables, and meat, which cannot be detected by color, shape, touch, or smell. Near-Infrared technology can identify and distinguish products based on their chemical composition. Hence, it is used for the processing of both plant and animal foods in the selection of raw materials to process control, ensure quality standards, and prevent adulteration.

Near-Infrared Spectroscopy

Near-infrared (NIR) is a portion of the light that lies next to the red color in the visible spectrum. It can detect the chemical bonds between the atoms in the organic compounds (i.e. the carbon-based compounds), which make up plants and animals. Hence, these compounds will absorb, reflect, or transmit varying amounts of NIR based on their composition. This property is called spectroscopy.

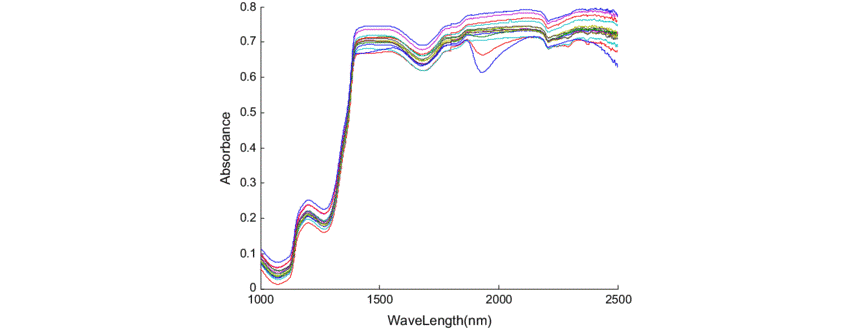

However, each compound will respond to only a particular wavelength within the NIR, so scientists have to identify this wavelength for each compound; see Figure 1.

Subscribe to the Felix instruments Weekly article series.

By submitting this form, you are consenting to receive marketing emails from: . You can revoke your consent to receive emails at any time by using the SafeUnsubscribe® link, found at the bottom of every email. Emails are serviced by Constant Contact

Then, NIR spectroscopy can be used to identify chemicals within a sample and the amounts in which are present.

Figure 1: Though there are differences in the spectra of juice from 15 different regions, they all peak at the same wavelengths, Dan et al. 2015. (Image credits: http://dx.doi.org/10.1080/10798587.2015.1095474)

Food Processing

The ability to detect chemical composition is increasingly being used to help in the processing of food.

Modern food products meant for the market need to be of uniform quality and standard. This can be difficult if only the external parameters of fruits or meat are used.

NIR spectroscopy, which provides detailed information on the internal characteristics, has many applications. The parameters analyzed by NIR in plant- and animal-based foods are as follows:

- Animal products: NIR spectroscopy can estimate fats, proteins, carbohydrates, and water content in animal samples.

- Plant products: Agricultural and horticultural crop processing units use dry matter, total soluble sugar (BRIX), titratable acidity, and water content as parameters.

To this end, NIR spectrometers are used in factories before, during, and after processing. In the case of fruits, the NIR examination of food needs to start at farms.

Fruit Processing

Fruits are used as fresh produce or made into products like juice, jam, wine, leather, etc. NIR is used to fix the harvest time of fruits so that they have the ideal chemical composition. NIR is also used for quality control of fruits post-harvest.

The requirements of the chemical composition will not be the same. Fruits that are processed into jams and wines are measured for sugar content.

Fruits used for juice-making need sugars, such as glucose, fructose, and sucrose, but also some acidity. The acids usually measured are ascorbic acid, citric acid, malic acid, and lactic acid.

Harvest Time

NIR helps to fix the right time to harvest fruits and vegetables so that they have the desired levels of sugar and dry matter.

- If the fruits are non-climacteric, like berries or grapes, BRIX is used to measure the total soluble sugars is used.

- In climacteric fruits that will continue to ripen after harves, like apples and mangoes, dry matter content is used to fix harvest time. Research has established that dry matter is a good predictor of the fruit sweetness post-harvest.

Selection and Monitoring

When processors get produce from multiple sources, simple portable NIR tools are useful during many steps of selection and monitoring:

- Fruit Selection: NIR tools help them to assess the sugar content of different batches of fruits. They can then choose to select fruits that are similar in sugar content or mix crops to get optimum quality parameters.

- Processing: During juice production, producers have to ensure that they reach the strict standards of sugar and acidity prescribed by the juice industry. During processing, the amount of water content can also be monitored easily by NIR.

- Drying: In the case of dry fruit production, like with raisins, it is the moisture content that is important before and during the drying process. There is 60 to 96% of water content in fruits, depending on the type of fruit. During processing, this high level of moisture is reduced.

- Maintaining Quality Standards: NIR is also used to ensure that the levels of adulterants are below acceptable standards, as adulteration with cheap substitutes is a common problem.

Felix Instruments has a range of Quality Meters that can measure dry matter, BRIX, external and internal color, titrable acidity, and moisture content. The tools have a GPS, so they can be used with Fruit Maps and benefit from local information about crops.

The F-750 Produce Quality Meter is a universal tool that can be used for several fruits and vegetables.

Below are other tools which have been customized for use for specific fruits:

Oil Production

Vegetable oil is the leading food produced, and alone it accounts for 40% of all agricultural crop production. Vegetable oils are produced from soybeans, sunflower, safflower, palm, coconut, cotton, olives, and canola.

Oil production is also a significant sector that uses NIR spectroscopy to estimate oil, water content, and protein content in the seeds or flesh.

In olive oil, NIR is also used to fix harvest time. Olive oil is different from other vegetable oils as there are various grades of oils with a difference in taste. It has been found that leaving olives on trees for a longer amount of time increases the oil content in the flesh, but impacts the flavor of the oil. Moreover, the levels of phytophenols, such as hydroxytyrosol—which are also crucial for flavor and nutritional benefits—are higher in younger fruits. So, in the case of olive oil, fruits are picked earlier to make high-quality oils, and olives that are harvested later are used to make lower grades of olive oils.

Farmers use NIR to estimate dry matter, a good predictor of oil content, to fix harvest dates depending on the grade of oil that is being produced.

In the processing unit, olives are tested so that fruits of similar chemical composition can be used to get a homogeneous product.

Milk and Cheese Production

The compounds that are analyzed the most, during milk and cheese production, are fat and water content.

Milk Homogenization

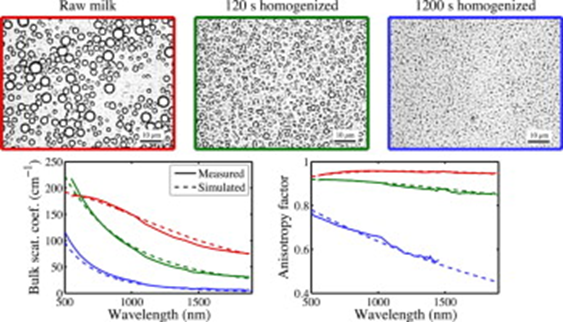

Milk, usually obtained from cows, buffalos, goats, and sheep, is sold after it is pasteurized. Usually, a second process called homogenization is conducted. In raw milk, the fat, which exists as globules, tends to float and accumulate on top. In homogenized milk, the fat globules are broken so that they are more evenly distributed in the entire liquid volume.

Homogenized milk has a more extended shelf-life, a better taste, and can easily allow for mixing milk from different herds with varying fat content.

After homogenization, it is possible to skim the fat to produce milk that is low-fat or even completely fat-free.

NIR is useful in estimating fat globule size, as they have different spectral signatures, as shown in Figure 2. So, it is used before, during, and after homogenization.

Figure 2: Difference in size of fat globules in milk alters the absorption and scattering of NIR, Aeronouts, et al. 2015. (Image credits: https://doi.org/10.1016/j.colsurfb.2015.01.004)

Cheese Production

Cheesemaking is a vast industry that is increasingly getting mechanized and larger in scale. NIR is useful in practically all of the steps involved in making an extensive range of cheese.

- Standardizing milk: The fat to protein ratios of milk to make different kinds of cheese is fixed and follows industry standards. NIR can analyze milk from various sources to ensure that the mixture finally has the correct amounts of fat and casein, the crucial protein.

- Renneting: This is the most common process used to coagulate milk, the first step in making any cheese. Coagulation happens in three stages: liquid, transition, and solid. Each stage has a unique spectral signature with specific fat levels. So, it is possible to monitor if the whole process is occurring correctly.

When coagulation is complete, the solid portion separates from whey at a point called cutting. NIR has been able to correctly determine the optimum cutting point for various types of cheese. It ensures that there is less loss of cheese and also optimizes quality. - Pressing: This process removes moisture from the blocks of curds. NIR is used to track water content reduction in the entire step.

- Aging: Similarly, throughout aging, the content of fat and water are measured by NIR not just on the surface but also inside blocks, as NIR can penetrate deep into samples.

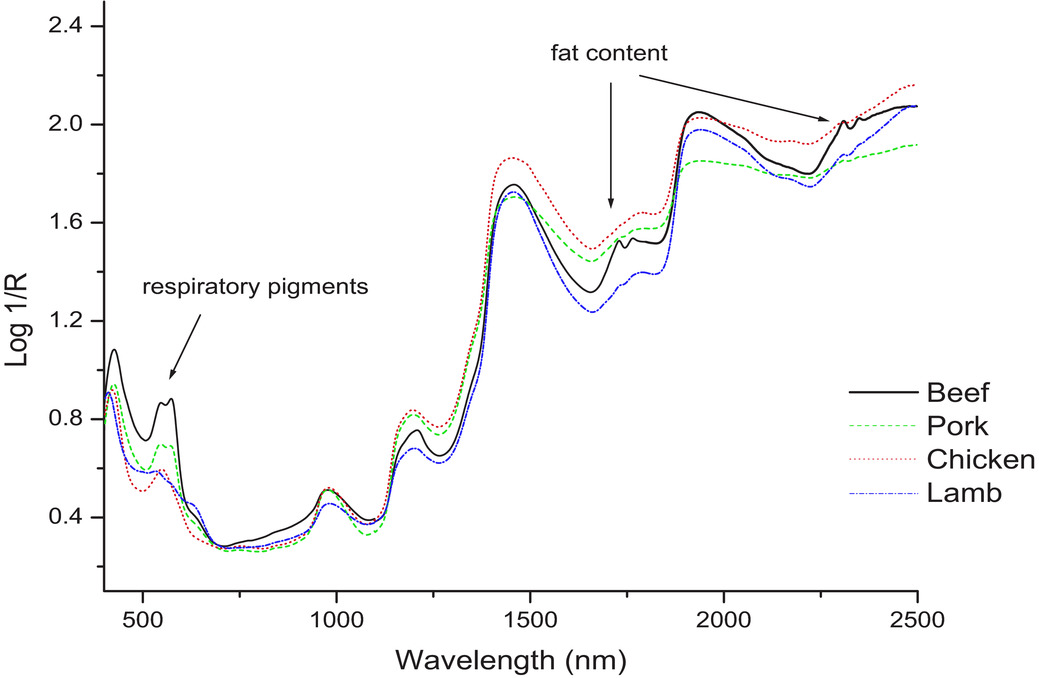

Meat Products

Figure 3: “Visible and NIR spectra of beef, pork, chicken, and lamb meat, adapted from Cozzolino and Murray 2004).” (Image credits: https://onlinelibrary.wiley.com/doi/full/10.1111/1541-4337.12295)

Similar to cheese, meat product processing also uses NIR for chemical composition estimation to help in many tasks. Some of the most common ones are discussed below:

- Selection of raw material: NIR is used to find the protein, fat, and moisture content of minced mixtures used to make sausages. It is also useful in-line for large-scale production where frozen meat is minced in grinders.

- Aging: Many meat products like beef cuts are dried during the aging process to improve flavor. NIR is used to detect the external and internal moisture content of steaks non-destructively without damaging the value of the meat. As a result, microbial contamination is also limited.

- Tenderness: NIR can measure the tenderness of cooked aged beef, as tougher meat absorbs more light than tender samples.

- Detect adulteration: Cheaper meat is sold in places of expensive types. It is challenging to differentiate meat cuts and ground meat by color or consistency. NIR helps producers determine the species from which their ground meat is derived. Fat and protein content is used to detect pork in lamb and chicken/horse in beef samples. Spectral signatures can also differentiate between meat cuts from various muscle types within an animal.

The F-750 Produce Quality Meter can be used for analyzing meat samples, after models are built for specific meat types.

Advantages of NIR

NIR can replace conventional methods that require a lot of time, chemicals, and money. NIR spectrometers can be handy portable tools that are useful in the farm and small processing units. Others are made for use in-line, on-line, or at-line for large scale processing units. Both kinds of tools have the advantage of providing a rapid and accurate analysis that is also non-destructive. The results are available in real time, so that changes can be made immediately during processes to correct and refine them. NIR helps to make processing more precise, improves monitoring and process control, increases end yield, and, lastly, guarantees excellence in quality.

—

Vijayalaxmi Kinhal

Science Writer, CID Bio-Science

Ph.D. Ecology and Environmental Science, B.Sc Agriculture

Feature image courtesy of Ajay Rai

Sources

Dixit, Y., Casado-Gavalda, M. P., Cama-Moncunill, R., Cama-Moncunill, X., Markiewicz-Keszycka, M., Cullen, P. J., & Sullivan, C. (2017). Developments and Challenges in Online NIR Spectroscopy for Meat Processing. Comprehensive Reviews in Food Science and Food Safety, 16(6), 1172–1187. doi: 10.1111/1541-4337.12295

García-Sánchez, F., Galvez-Sola, L., Martínez-Nicolás, J.J., Muelas-Domingo, R., & Nieves, M. (2017). Using Near-Infrared Spectroscopy in Agricultural Systems. Developments in Near-Infrared Spectroscopy. Editors: Kyprianidis, K., & Skvaril, J. Tech Open. DOI: 10.5772/67236

Haggag, L., Shahin, M.F.M., Genaidy, E.A.E. & Fouad, A.F. (2013). Changes in Fruit weight, dry matter, Moisture content and Oil percentage during fruit development stages of two olive cultivars. Middle East Journal of Agriculture Research, 2, 21-27. Retrieved from http://www.curresweb.com/mejar/mejar/2013/21-27.pdf

Aernouts, B., Beers, R. V., Watté, R., Huybrechts, T., Jordens, J., Vermeulen, D., … Saeys, W. (2015). Effect of ultrasonic homogenization on the Vis/NIR bulk optical properties of milk. Colloids and Surfaces B: Biointerfaces, 126, 510–519. doi: 10.1016/j.colsurfb.2015.01.004

Spiegel, A. (2016, November 29). Pasteurized vs. Homogenized Milk: What’s The Difference? Retrieved from https://www.huffpost.com/entry/pasteurized-homogenized-milk_n_5606168

Castillo, M. (2010). Cheese Making: Cutting Time Prediction. Encyclopedia of Agricultural, Food, and Biological Engineering, Second Edition, 218–224. doi: 10.1081/e-eafe2-120040365

Grassi, S., Strani, L., Casiraghi, E., & Alamprese, C. (2019). Control and Monitoring of Milk Renneting Using FT-NIR Spectroscopy as a Process Analytical Technology Tool. Foods, 8(9), 405. doi: 10.3390/foods8090405

Nicolau, N., Buffa, M., O’callaghan, D. J., Guamis, B., & Castillo, M. (2015). Estimation of clotting and cutting times in sheep cheese manufacture using NIR light backscatter. Dairy Science & Technology, EDP sciences/Springer, 2015, 95: 495-507. 10.1007/s13594-015-0232-7. hal-01312523

Šnurkovič, P. (2013). Quality assessment of fruit juices by NIR spectroscopy. Acta Universitatis Agriculturae Et Silviculturae Mendelianae Brunensis, 61(3), 803–812. doi: 10.11118/actaun201361030803

Related Products

- F-901 AccuRipe & AccuStore

- F-751 Melon Quality Meter

- F-751 Kiwifruit Quality Meter

- F-750 Produce Quality Meter

- F-751 Avocado Quality Meter

- F-751 Mango Quality Meter

- F-900 Portable Ethylene Analyzer

- F-950 Three Gas Analyzer

- F-920 Check It! Gas Analyzer

- F-960 Ripen It! Gas Analyzer

- F-940 Store It! Gas Analyzer

Most Popular Articles

- Spectrophotometry in 2023

- The Importance of Food Quality Testing

- NIR Applications in Agriculture – Everything…

- The 5 Most Important Parameters in Produce Quality Control

- Liquid Spectrophotometry & Food Industry Applications

- Melon Fruit: Quality, Production & Physiology

- Ethylene (C2H4) – Ripening, Crops & Agriculture

- Active Packaging: What it is and why it’s important

- Guide to Fresh Fruit Quality Control

- Understanding Chemometrics for NIR Spectroscopy